MIT Engineers Make Filters From Tree Branches To Purify Drinking Water

Prototypes tested in India show promise as a low-cost, natural filtration option.

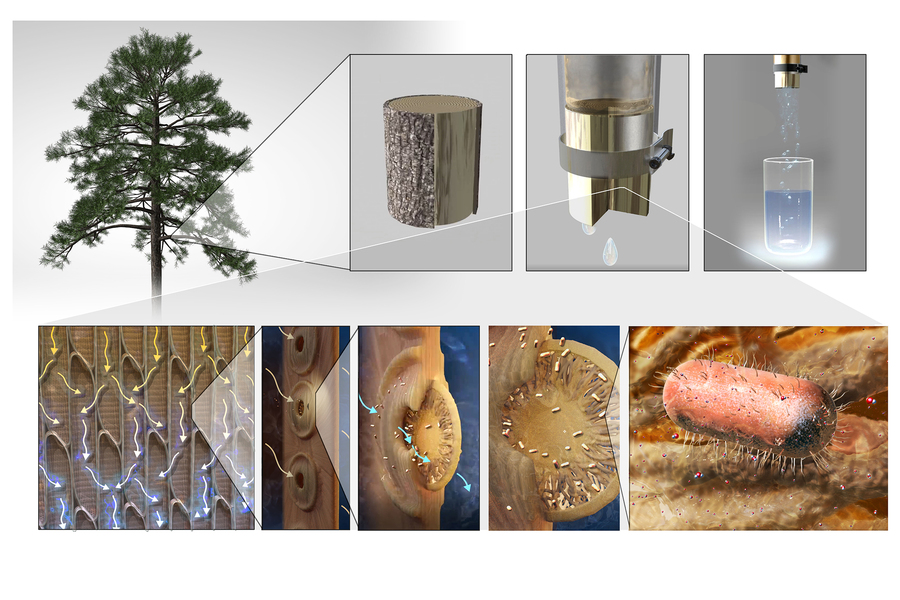

The interiors of nonflowering trees such as pine and ginkgo contain sapwood lined with straw-like conduits known as xylem, which draw water up through a tree’s trunk and branches. Xylem conduits are interconnected via thin membranes that act as natural sieves, filtering out bubbles from water and sap.

The interiors of nonflowering trees such as pine and ginkgo contain sapwood lined with straw-like conduits known as xylem, which draw water up through a tree’s trunk and branches. Xylem conduits are interconnected via thin membranes that act as natural sieves, filtering out bubbles from water and sap.

MIT engineers have been investigating sapwood’s natural filtering ability, and have previously fabricated simple filters from peeled cross-sections of sapwood branches, demonstrating that the low-tech design effectively filters bacteria.

Now, the same team has advanced the technology and shown that it works in real-world situations. They have fabricated new xylem filters that can filter out pathogens such as E. coli and rotavirus in lab tests, and have shown that the filter can remove bacteria from contaminated spring, tap, and groundwater. They also developed simple techniques to extend the filters’ shelf-life, enabling the woody disks to purify water after being stored in a dry form for at least two years.

The researchers took their techniques to India, where they made xylem filters from native trees and tested the filters with local users. Based on their feedback, the team developed a prototype of a simple filtration system, fitted with replaceable xylem filters that purified water at a rate of one liter per hour.

Their results, published today in Nature Communications, show that xylem filters have potential for use in community settings to remove bacteria and viruses from contaminated drinking water.

The researchers are exploring options to make xylem filters available at large scale, particularly in areas where contaminated drinking water is a major cause of disease and death. The team has launched an open-source website, with guidelines for designing and fabricating xylem filters from various tree types. The website is intended to support entrepreneurs, organizations, and leaders to introduce the technology to broader communities, and inspire students to perform their own science experiments with xylem filters.

“Because the raw materials are widely available and the fabrication processes are simple, one could imagine involving communities in procuring, fabricating, and distributing xylem filters,” says Rohit Karnik, professor of mechanical engineering and associate department head for education at MIT. “For places where the only option has been to drink unfiltered water, we expect xylem filters would improve health, and make water drinkable.”

Karnik’s study co-authors are lead author Krithika Ramchander and Luda Wang of MIT’s Department of Mechanical Engineering, and Megha Hegde, Anish Antony, Kendra Leith, and Amy Smith of MIT D-Lab.

https://www.youtube.com/watch?embeds_referring_euri=https%3A%2F%2Fnews.mit.edu%2F&v=RujY7JsSrVQ

Clearing the way

In their prior studies of xylem, Karnik and his colleagues found that the woody material’s natural filtering ability also came with some natural limitations. As the wood dried, the branches’ sieve-like membranes began to stick to the walls, reducing the filter’s permeance, or ability to allow water to flow through. The filters also appeared to “self-block” over time, building up woody matter that clogged the conduits.

Surprisingly, two simple treatments overcame both limitations. By soaking small cross-sections of sapwood in hot water for an hour, then dipping them in ethanol and letting them dry, Ramchander found that the material retained its permeance, efficiently filtering water without clogging up. Its filtering could also be improved by tailoring a filter’s thickness according to its tree type.

The researchers sliced and treated small cross-sections of white pine from branches around the MIT campus and showed that the resulting filters maintained a permeance comparable to commercial filters, even after being stored for up to two years, significantly extending the filters’ shelf life.

https://www.youtube.com/watch?embeds_referring_euri=https%3A%2F%2Fnews.mit.edu%2F&v=tVye2AViBig

The researchers also tested the filters’ ability to remove contaminants such as E. coli and rotavirus — the most common cause of diarrheal disease. The treated filters removed more than 99 percent of both contaminants, a water treatment level that meets the “two-star comprehensive protection” category set by the World Health Organization.

“We think these filters can reasonably address bacterial contaminants,” Ramchander says. “But there are chemical contaminants like arsenic and fluoride where we don’t know the effect yet,” she notes.

Groundwork

Encouraged by their results in the lab, the researchers moved to field-test their designs in India, a country that has experienced the highest mortality rate due to water-borne disease in the world, and where safe and reliable drinking water is inaccessible to more than 160 million people.

Over two years, the engineers, including researchers in the MIT D-Lab, worked in mountain and urban regions, facilitated by local NGOs Himmotthan Society, Shramyog, Peoples Science Institute, and Essmart. They fabricated filters from native pine trees and tested them, along with filters made from ginkgo trees in the U.S., with local drinking water sources. These tests confirmed that the filters effectively removed bacteria found in the local water. The researchers also held interviews, focus groups, and design workshops to understand local communities’ current water practices, and challenges and preferences for water treatment solutions. They also gathered feedback on the design.

“One of the things that scored very high with people was the fact that this filter is a natural material that everyone recognizes,” Hegde says. “We also found that people in low-income households prefer to pay a smaller amount on a daily basis, versus a larger amount less frequently. That was a barrier to using existing filters, because replacement costs were too much.”

With information from more than 1,000 potential users across India, they designed a prototype of a simple filtration system, fitted with a receptacle at the top that users can fill with water. The water flows down a 1-meter-long tube, through a xylem filter, and out through a valve-controlled spout. The xylem filter can be swapped out either daily or weekly, depending on a household’s needs.

The team is exploring ways to produce xylem filters at larger scales, with locally available resources and in a way that would encourage people to practice water purification as part of their daily lives — for instance, by providing replacement filters in affordable, pay-as-you-go packets.

“Xylem filters are mae from inexpensive and abundantly available materials, which could be made available at local shops, where people can buy what they need, without requiring an upfront investment as is typical for other water filter cartridges,” Karnik says. “For now, we’ve shown that xylem filters provide performance that’s realistic.”

This research was supported, in part, by the Abdul Latif Jameel Water and Food Systems Lab (J-WAFS) at MIT and the MIT Tata Center for Technology and Design.

Publication: Krithika Ramchander, et al., Engineering and characterization of gymnosperm sapwood toward enabling the design of water filtration devices, Nature Communications (2023) DOI : 1010.1038/s41467-021-22055-w

Original Story Source: Massachusetts Institute of Technology

Alerts Sign-up

Alerts Sign-up